Introduction

As the world shifts towards renewable energy sources, solar panels have become a dominant contributor to sustainable power generation. However, with the increasing deployment of solar technology comes the challenge of managing end-of-life solar panels. Recycling solar panels is essential to recover valuable materials, reduce waste, and ensure environmental sustainability. This article discusses a machine designed to recycle 1 ton per hour (1 t/h) of solar panels, highlighting its features, processes, and benefits.

Key Features of the Solar Panel Recycling Machine

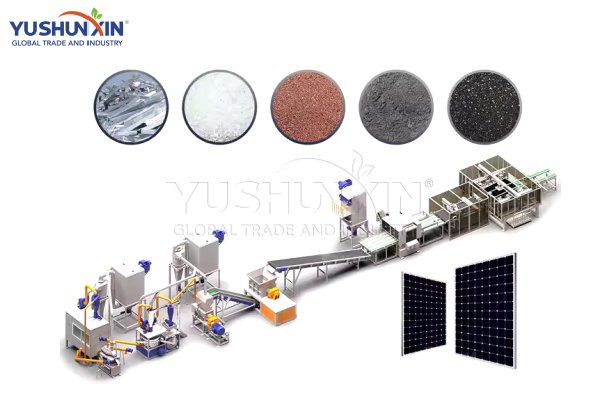

The solar panel recycling machine with a capacity of 1 t/h is engineered to handle the complexities of solar panel composition efficiently. Solar panels consist mainly of glass, metals like aluminum and silver, silicon, and polymers, each requiring careful processing to ensure effective recycling. The machine boasts robust construction and innovative technology to manage these diverse materials safely and efficiently.

This recycling system typically includes a crushing and shredding unit, separation technology, and purification processes. The crushing unit is vital for breaking down the panels into manageable pieces, while the separation technology classifies and isolates different materials. The purification processes ensure the recovery of high-quality materials suitable for reuse.

Recycling Process

The recycling operation begins with the collection and categorization of solar panels. Once sorted, panels are fed into the machine’s crushing unit, where they are reduced to smaller fragments. This stage is crucial for exposing the various layers and materials within the panels for subsequent processing.

Following crushing, the material moves into the separation phase. Techniques such as mechanical separation, electrostatic separation, and thermal processing are employed to isolate components like glass, metals, and silicon. For instance, glass, which constitutes a significant portion of solar panels, is separated and cleaned for reuse in new products.

In the purification stage, the extracted materials undergo further refining to ensure they meet industry standards for quality and purity. This may involve washing and chemical treatments to remove any residual contaminants. High-purity silicon, for example, can be reclaimed and used in the production of new solar cells.

Benefits of the 1 t/h Solar Panel Recycling Machine

The primary advantage of a machine capable of recycling 1 ton per hour of solar panels is its high efficiency, making it suitable for handling large volumes of waste in industrial settings. This capacity aids facilities in managing significant quantities of discarded panels, reducing the need for storage and minimizing environmental impact.

Environmental benefits are substantial, as the machine facilitates the recovery of valuable resources and supports the circular economy. By reclaiming materials like glass, aluminum, and silicon, the need for raw material extraction is reduced, conserving natural resources and minimizing carbon emissions associated with mining and production processes.

Conclusion

The 1 t/h solar panel recycling machine is a critical innovation in the pursuit of sustainable energy management. By efficiently processing end-of-life solar panels, it contributes to resource conservation and waste reduction. Through its advanced design and capabilities, the machine plays a vital role in promoting environmental sustainability and supporting the growth of renewable energy technologies. Visiting: https://www.solutionsforewaste.com/1000kg-h-solar-panels-recycling-plant-start-in-india/

Leave a Reply