Introduction to Solar Panel Recycling

As the adoption of solar energy continues to surge globally, the issue of solar panel waste becomes more pressing. Solar panels typically have a lifespan of 25 to 30 years, after which they may become inefficient or obsolete. With millions of panels now reaching the end of their life cycle, recycling them has become critical to ensure environmental sustainability and resource conservation. But how does a solar panel recycling machine work? This article explores the intricacies of the recycling process, shedding light on the technology and methodology involved.

Understanding the Composition of Solar Panels

- Materials in Solar Panels

Solar panels are primarily composed of glass, silicon, aluminum, silver, and various polymers. Glass accounts for the majority of a panel’s weight, while silicon cells are crucial for electricity generation. Aluminum frames provide structural support, and silver is used in the conductive connections. Effective recycling involves efficiently separating and reclaiming these valuable materials.

- Challenges in Recycling

The complexity of solar panel composition poses challenges for recycling. The materials are often bonded together with adhesives, making disassembly difficult. Moreover, the presence of hazardous materials, though minimal, requires careful handling to prevent environmental contamination.

The Recycling Process

- Initial Collection and Transportation

The recycling process begins with the collection and transportation of end-of-life solar panels to a recycling facility. Panels are often collected in bulk to optimize transportation efficiency and reduce costs.

- Disassembly and Material Separation

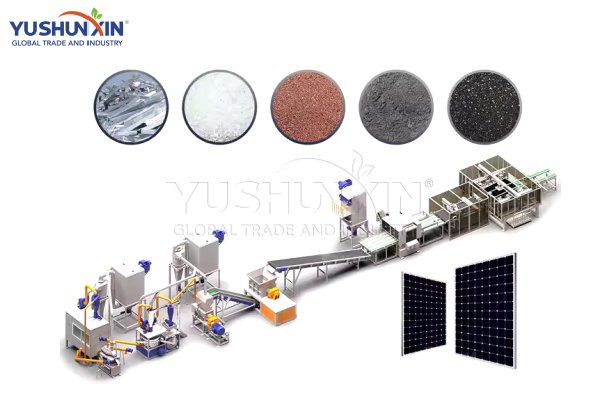

Once at the recycling facility, panels undergo a disassembly process. The aluminum frames and junction boxes are manually removed first. Advanced recycling machines are then employed to crush and shred the panels, breaking them down into smaller fragments for further processing.

- Thermal and Chemical Treatments

The crushed materials are subjected to thermal and chemical treatments to separate and purify the different components. High temperatures help to evaporate the polymers and separate the silicon from the glass. Chemical processes are used to recover valuable materials such as silver and other metals from the silicon cells.

End-Product and Reuse

- Recovery and Reuse of Materials

Recovered materials are processed and purified to meet industry standards. Glass and aluminum are relatively easy to recycle and can be reused in manufacturing new solar panels or other products. Silicon can be refined and reused for new photovoltaic cells, while metals like silver are reclaimed for various industrial applications.

- Environmental and Economic Benefits

Recycling solar panels conserves natural resources by reducing the need for raw material extraction. It also minimizes environmental impact by preventing waste from ending up in landfills. Economically, recycling creates new business opportunities and jobs in the green technology sector.

Conclusion

The operation of a solar panel recycling machine is a sophisticated process involving advanced technology and strategic methodologies. By efficiently recovering valuable materials, the recycling process not only addresses the environmental concerns associated with solar panel waste but also supports the sustainable growth of the solar industry. As technology advances, further innovations in recycling processes are expected to enhance efficiency and economic viability, contributing to a more sustainable future. Visiting: https://www.solutionsforewaste.com/product/solar-panel-recycling-machine/

Leave a Reply