Introduction to Solar Panel Recycling

As the world pivots towards renewable energy, solar panels have become a ubiquitous part of the energy landscape. However, with the increasing adoption of solar energy comes the challenge of managing end-of-life solar panels. Establishing a solar panel recycling business is a forward-thinking venture that addresses environmental concerns while tapping into the growing demand for sustainable waste management solutions. This business plan outlines the necessary equipment, labor requirements, and operating costs for a successful solar panel recycling operation.

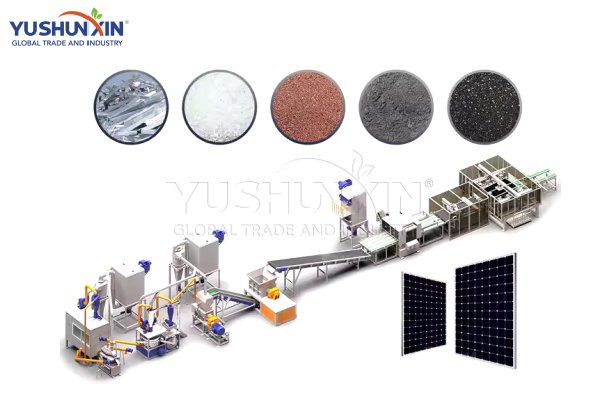

Essential Equipment for Solar Panel Recycling

A solar panel recycling facility must be equipped with specialized machinery to efficiently break down and process end-of-life panels.

- Panel Dismantling Tools: The first step involves dismantling the solar panels to separate the glass, silicon cells, and metal frames. Equipment costs for dismantling tools typically range from $15,000 to $40,000.

- Crushing and Grinding Machines: These machines are crucial for crushing the dismantled panels into smaller pieces, facilitating material separation. Depending on capacity and technology, the cost can vary from $50,000 to $150,000.

- Separation and Sorting Systems: Once crushed, the material needs to be sorted to recover valuable components like silicon, silver, and aluminum. This requires magnetic separators, eddy current separators, and optical sorting machines, with a combined cost of around $60,000 to $200,000.

Labor Requirements

Efficient operations require a well-trained workforce to handle various stages of the recycling process.

- Skilled Technicians: Technicians are responsible for operating and maintaining machinery. Hiring and training skilled technicians can cost around $50,000 to $70,000 annually per technician, depending on experience and location.

- General Labor: Support staff for tasks such as loading, unloading, and manual sorting are essential. Labor costs for these roles can range from $30,000 to $50,000 annually per worker.

- Management and Administrative Staff: A team to oversee operations, handle logistics, and manage finances is crucial. Salaries for management staff can be between $70,000 and $120,000 annually.

Operating Costs and Considerations

Operating a solar panel recycling facility involves various costs beyond equipment and labor.

- Utilities and Maintenance: The cost of electricity, water, and regular maintenance for the equipment can range from $5,000 to $15,000 monthly, depending on the facility size and location.

- Permits and Compliance: Ensuring compliance with environmental regulations requires permits, which can cost between $10,000 and $30,000 annually. Regular inspections and environmental audits are also part of ongoing compliance costs.

- Transportation and Logistics: Transporting end-of-life panels to the recycling facility and distributing recovered materials incurs additional costs, typically ranging from $20,000 to $50,000 annually.

Conclusion

A solar panel recycling business presents a promising opportunity to contribute to environmental sustainability while generating revenue. By investing in the right equipment, assembling a skilled workforce, and managing operating costs efficiently, entrepreneurs can establish a competitive and impactful operation. As the solar industry continues to grow, so too does the potential for innovative recycling solutions to play a crucial role in a sustainable future. Visiting: https://www.solutionsforewaste.com/product/solar-panel-recycling-plant-cost/

Leave a Reply